By Marc Venis B.A.Sc., M.A.Sc., P.Eng., President Vencon Technologies Inc.

The key to preventing battery failures is to minimize any misuse and to track their capacity and other key characteristics. A battery monitoring program will identify a rapidly deteriorating battery before it actually fails.

The first part of a battery monitoring program is to regularly measure their capacity. Capacity is the amount of charge available from a battery, measured in ampere-hours (Ah) for large cells, milliampere-hours (mAh) for smaller cells. A typical AA size battery has a rated capacity of 600mAh, thus it can supply 600mA for at least one hour or 100mA for at least six hours. Manufacturers conservatively rate battery capacity so that, in general, the measured capacity (which we discuss below) should be greater than the rated amount.

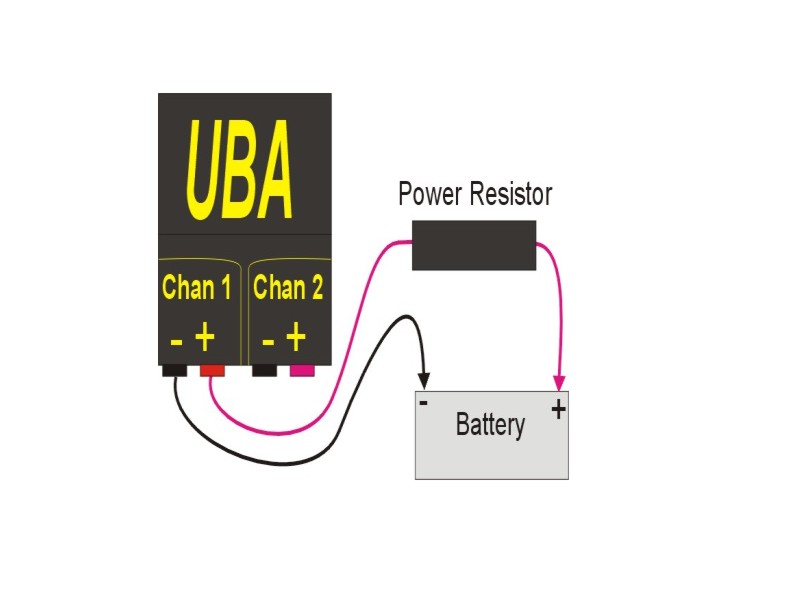

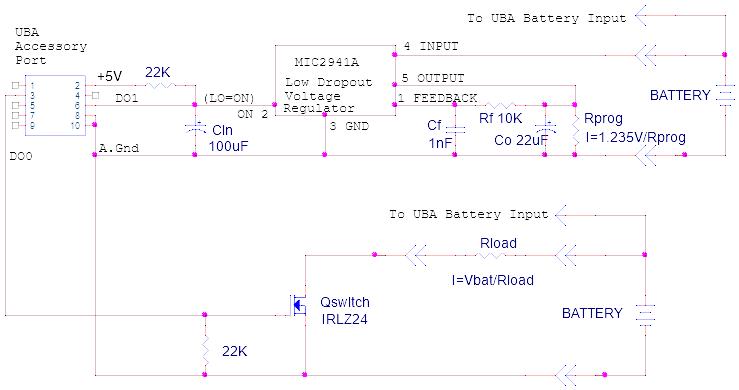

The basic concept used by all battery analyzers to check capacity is to connect the battery to a known accurate constant current load and monitor the voltage as the battery discharges (figure 1).

When the battery voltage reaches a predetermined value (the cut off voltage), the load is disconnected and the elapsed time recorded. The battery capacity is simply the load current times the elapsed time in hours. Normally, you would start this test with a fully charged battery. You can check a battery’s capacity using this method with only a resistor as load, a voltmeter, and a stop watch. Alternately, you can use a commercial battery analyzer (such as the Ultimate Battery Analyzer our company makes).

There are many commercial analyzers available, ranging in price from $200 to $2000 or more. The best one for you depends on features you need and your budget. The less expensive models are limited in their accuracy and customization. The more expensive models allow you to test more types of batteries and many batteries at once.

Operation of all the commercial units is similar: first, connect a power source to the analyzer, an AC plug, a wall adapter (power supply) or a 12V battery. Specify the battery being tested (i.e. a Motorola 550 cell phone) or specify the test conditions (i.e. number of cells, charging and discharging current, depth of discharge). Then connect the analyzer to the battery that is being tested. Press the start button and leave the analyzer and battery alone for a few hours. The analyzer discharges the battery, measures the discharge time then recharges the batteries. After the discharge is completed the analyzer shows your battery’s capacity.

The measured capacity depends on the following factors: battery temperature, discharge current, cut-off voltage, and the battery’s prior history. Below room temperature (20 degree C) battery capacity is reduced. You should make all your measurements between 18 degree C and 25 degree C.

What discharge current should you use? Most manufacturers (Sanyo and Panasonic for example), measure capacity at a discharge rate of C/5, which is called the five hour discharge rate. For example, a typical AA cell of 600mAh capacity would have a ‘C’ of 600mA and a C/5 of 120mA. Others measure capacity at a discharge rate of C. Like all batteries, the higher the discharge current, the less the available capacity. For example, the available capacity with a discharge at C/5 is about 10% more than that with a discharge at the C rate. Another possible discharge current would be the actual current drain of the battery while being used. I recommend that you discharge at between C and C/2.

At what point do you stop the discharge? If you choose too high of a figure, you won’t fully discharge the cells. If you choose too low a figure, you might force one of the cells into reverse polarity (not a good situation). Usually a cut-off voltage of 1.05V/cell is used when discharging at the C/5 rate and 0.9V/cell when discharging at the C rate. Or you can use the formula:

Vcutoffper_pack=1.2V * (Ncells-1)

Which gives a cut off of 0.9V per cell for a four cell battery pack, and 1.05V for an eight cell battery pack.

What does prior history have to do with a battery’s capacity? A battery that was quick charged or charged at above room temperature will not generally be fully charged. Nor will a battery that was charged after being stored for a few months. For these reasons I recommend that before a capacity test, the battery be charged at C/10 for 18 hours to 24 hours at room temperature. If the battery had been stored for a few months, is new, or hasn’t been tested in a few months, a second and possibly a third capacity test is recommended.

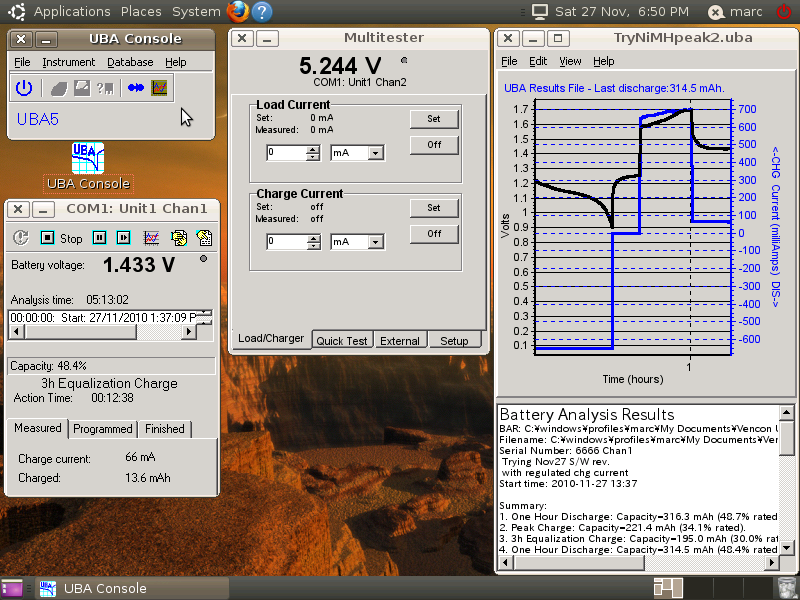

One additional measurement you can make during a discharge experiment is the “midpoint voltage.” This is the voltage midway through a discharge test. If you have our Ultimate Battery Analyzer, you can simply read it off the graph (midpoint voltage figure 2), otherwise you will have to use an accurate voltmeter to measure the voltage yourself during the battery discharge. Record this voltage.

Windows 10 Compatible

Windows 10 Compatible